Perfectly shaped: The Future of 3D Printed Insoles in the Craft Industry

3D printing in orthopedic footwear technology is developing rapidly. No wonder, after all, orthopedic insoles from the printer promise low effort, optimal material utilization and perfect fit. It's often not so easy to keep up to date with all the technical innovations. And of course the question arises as to whether printed insoles can really keep up with conventional manufacturing processes.

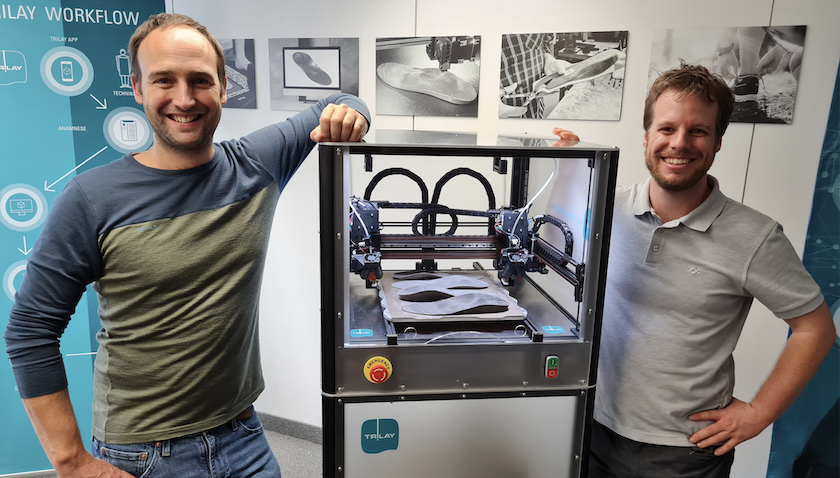

Christian Tausch (on the left in the picture) and Dominic Ring (on the right in the picture) are certain that printed orthopedic insoles are the future of the trade and are already paying off. For three years, the duo - jokingly known in their local workshop as "Team Jetrieb" - has been tinkering with printers, processes and materials that deliver the highest quality and at the same time take the pressure off businesses. In an interview, the master orthopedic shoemaker and the mechanical engineer explain what they have discovered and what to look out for when getting started.

First things first: Printing orthopedic insoles - is that even possible yet in sufficiently high quality?

CT: It's definitely possible! With the necessary know-how, the appropriate technology and proven materials, FDM (fused deposition modeling) printing today holds its own well with conventional manufacturing processes. In the beginning, we could hardly believe the high quality we could achieve in terms of durability and effectiveness. Easily comparable with the results of previous processes! In the meantime, it has turned out: The first good experiences were no coincidence, we can really reliably create first-class quality with FDM printing. This is also reflected in the feedback from our customers.

FDM printing, that's the so-called "sausage printing", isn't it? Isn't that qualitatively inferior to resin printing, for example?

DR: Well, nobody really says "sausage printer" anymore (laughs). A few years ago, when 3D printing as a whole was still in its infancy, there were a few challenges. But in the meantime, those have been overcome.

We have very good experience with FDM printing results. For example, with this process we can combine different printing materials excellently with each other. Our customers and trade show visitors also confirm to us again and again that the printed inserts can be processed excellently and are of great quality.

That sounds interesting. So you can already combine different Shore hardnesses with each other?

DR: Yes, absolutely! We print everything from rock-hard to super-soft in an insole and thus achieve versatile functional properties. Stable, bedding, shell insoles, rigid springs... we can now do a lot of things.

But isn't there a risk when combining different materials that the stability of the insole will suffer and, in the worst case, it will literally fall apart?

CT: Not with the right printing process. We now know very well how to combine materials of different degrees of hardness and reliably bond them together. For the production of orthopedic insoles, it is central that we can use the material properties precisely. Only in this way can we enable stiffening and relief directly in compression, guarantee individuality and medical benefit, and of course also produce in accordance with the aids catalog. A heel spur pad, for example, only provides optimum relief if it has the right cushioning properties and sits in the right position.

Sounds good, but it's not quite easy to imagine. How does that work?

DR: You can achieve a lot here via the printing strategy - up to a certain point. In order to expand the range of properties beyond that, we have specifically tested additional materials here and systematically tried out possible combinations. That's how we know which material is best suited for a particular property.

The keyword here is orthopedic insoles - the printing material has to be specially certified. Isn't that expensive and time-consuming?

DR: Good point. Poor filament quality is actually the biggest enemy of good prints. That's why we took a lot of time in developing our offering to provide the optimal material for orthopedic insoles. The TRILAY SL filament is not only certified, but is also a high speed TPU filament. This allows very high printing speeds to be realized.

CT: Exactly, we can also offer a wide range of colors. After all, that is important for the branding of the companies. Logos can also be printed on without any problems. But even more important is that the removal-resistant labeling enables complete, MDR-compliant documentation. This makes everyday work much easier.

But is 3D printing worth it? Materials and energy aren't exactly cheap.

CT: The changeover is definitely worthwhile. We have worked on massively reducing printing time and have also been able to optimize preheating, for example. This reduces energy consumption and waiting times. A major advantage is, of course, that there is virtually no waste. This not only saves money, but also protects the environment. Old inserts can also be recycled.

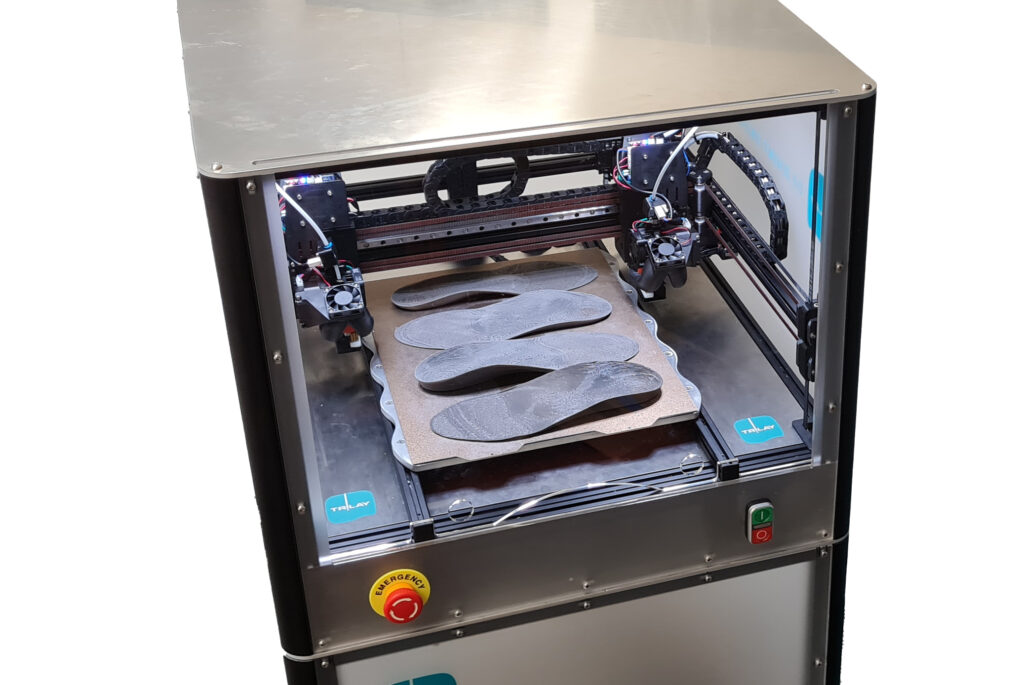

DR: To put it into numbers... a 3D printer that produces insoles all day uses an average of just under 2kWh per day. If you compare that with the energy consumption of a conventionally milled insert, the savings are around 20%. On the subject of waste: milling, for example, produces around 80% waste and requires a large stock of blanks. With 3D printing, these disadvantages simply do not apply.

CT: Correct. In addition, the TRILAY process requires only minimal post-processing. In most cases, simply roughen, cover, and you're done. Depending on requirements, however, the insert can also be sanded and glued as usual in the event of unforeseen changes. The working time of highly qualified employees can be used more effectively, and this must be taken into account in the calculation.

With resin printing, by the way, it's different. In fact, several more steps are necessary after printing until the inlay is really finished. And that involves the use of chemicals and special tools. A clear advantage for FDM printing, I would say.

Overall, then, most companies with the right 3D printing process are likely to produce particularly cost-effectively.

However, that still leaves the printer, which also costs money to buy.

CT: Sure, but to make it easier to get started we offer different models. From print service to capacity rental to purchase, we offer many options. In this way, we want to ensure that businesses of all sizes have access to 3D printing technology.

DR: You don't have to buy any software either. The simplest access is free of charge, you can simply apply for it and get started in the webshop.

Many orthopedic shoemakers are likely to be skeptical about this. Do craftsmen have to worry about being replaced?

CT: No, absolutely not. I've been a master orthopedic shoemaker myself for a long time, have known the craft from an early age, and also try to keep the family tradition open for my children. Craft is a matter of the heart for me. The skilled workers will definitely also be needed in the future, without them nothing works. Their experience and know-how are indispensable for ensuring the quality of care. Without skilled workers, the high demands could not be met at all.

DR: That's why it's important for us to involve the workforce when a company introduces 3D printing. You have to look at what is needed on an individual basis. We are happy to provide advice and support. However, our experience shows that after a short changeover phase, employees also benefit from the technology. After all, the quality of the workplace increases when there is less milling: Lower dust and noise levels are not only more pleasant, but also simply healthier. In addition, many enjoy learning new things, working in a progressive way and also having more time for consulting, for example.

And how can you learn more about the possibilities of 3D-printed insoles?

CT: We prefer to speak directly with interested parties. We are happy to take the time to present our products, test the online insole configurator together, answer any questions, and address any concerns. At trade fairs, we are always happy to see you, and you can always make a personal appointment on our homepage.

It is often only then that you realize that getting started is much easier than you first thought.

Interviewer: Verena Pachler